Predictive Analytics for Equipment Failure

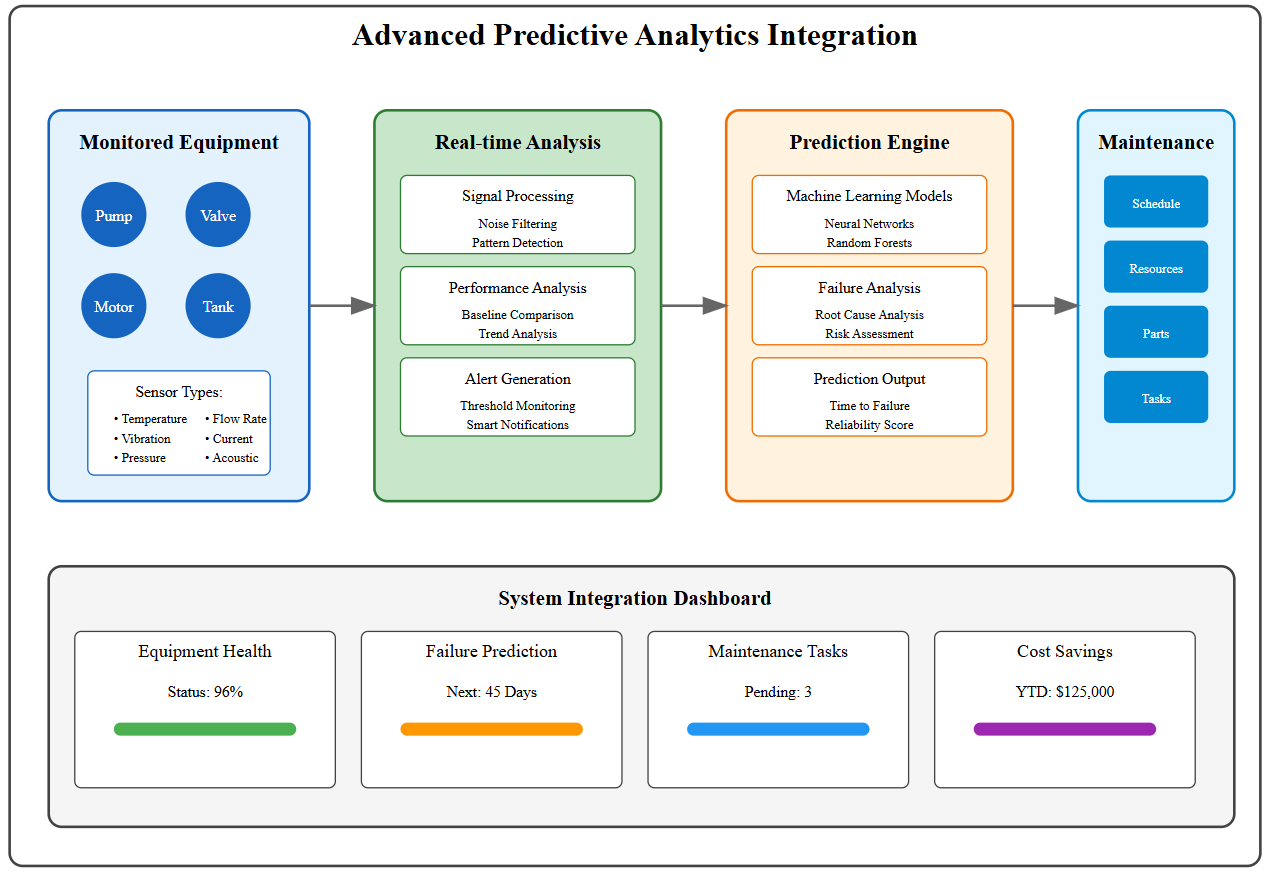

Crestocean Energy's Predictive Analytics Suite transforms equipment maintenance through three integrated solutions that work together to prevent failures and optimize performance.

Our system combines real-time monitoring, advanced prediction algorithms, and intelligent maintenance scheduling to maximize equipment reliability and reduce operational costs.

Real-time Performance Monitor

The Real-time Performance Monitor serves as your equipment's constant guardian, providing continuous insight into operational health. This solution delivers:

Advanced Sensor Integration

The system collects and analyzes data from multiple sensor types, monitoring critical parameters such as temperature, vibration, pressure, and flow rates. Our intelligent sensors adapt to varying operational conditions, ensuring accurate data capture even in challenging environments.

Performance Analysis

Through sophisticated signal processing and pattern recognition, the system continuously evaluates equipment performance against established baselines. This enables early detection of developing issues before they become critical problems.

Dynamic Alerting

The solution provides intelligent alerts based on both absolute thresholds and trend analysis, reducing false alarms while ensuring no critical events are missed.

Failure Prediction Engine

Our Failure Prediction Engine uses advanced machine learning algorithms to forecast potential equipment issues with unprecedented accuracy. This solution incorporates:

Multi-model Analysis

The system employs multiple prediction models, each specialized for different failure modes and equipment types. These models work in concert to provide comprehensive failure prediction across your entire operation.

Pattern Recognition

By analyzing historical failure data alongside current operational parameters, the system identifies subtle patterns that precede equipment failures. This enables intervention before critical failures occur.

Risk Assessment

The engine provides detailed risk assessments for each piece of equipment, helping prioritize maintenance activities and resource allocation.

Maintenance Optimization Platform

The Maintenance Optimization Platform transforms predictive insights into actionable maintenance plans. This solution delivers:

Intelligent Scheduling

The platform creates optimal maintenance schedules that balance equipment reliability with operational requirements and resource availability. It considers factors such as maintenance crew availability, spare parts inventory, and production schedules.

Resource Optimization

Through intelligent resource allocation and task prioritization, the system helps maximize maintenance efficiency while minimizing operational disruption.

Cost Analysis

The platform provides detailed cost-benefit analysis for maintenance activities, helping optimize maintenance spending while maintaining equipment reliability.

Integration Benefits: The three solutions work together seamlessly to provide:

-

Reduced unexpected downtime

-

Lower maintenance costs

-

Extended equipment life

-

Optimized maintenance scheduling

-

Improved operational efficiency